News

NAEC Friendly Use Automatic Welding Flux Recycling System.

- Categories:News Center

- Author:

- Origin:

- Time of issue:2019-08-08 09:55

- Views:

(Summary description)NAEC pipe spool SAW welding flux feeding in recycling system mainly consists of flux hopper, flux collection trolley, dedusting system and control system, etc.

NAEC Friendly Use Automatic Welding Flux Recycling System.

(Summary description)NAEC pipe spool SAW welding flux feeding in recycling system mainly consists of flux hopper, flux collection trolley, dedusting system and control system, etc.

- Categories:News Center

- Author:

- Origin:

- Time of issue:2019-08-08 09:55

- Views:

Welding flux feeding in recycling system

NAEC pipe spool SAW welding flux feeding in recycling system mainly consists of flux hopper, flux collection trolley, dedusting system and control system, etc.

Flux hopper is installed on welding head while dedusting system is installed on welding main machine, motorized traveling along with welding main machine. There are four universal wheels fixed on the flux collection trolley bottom base, which is convenient for moving according to welding joint and main machine position at any time.

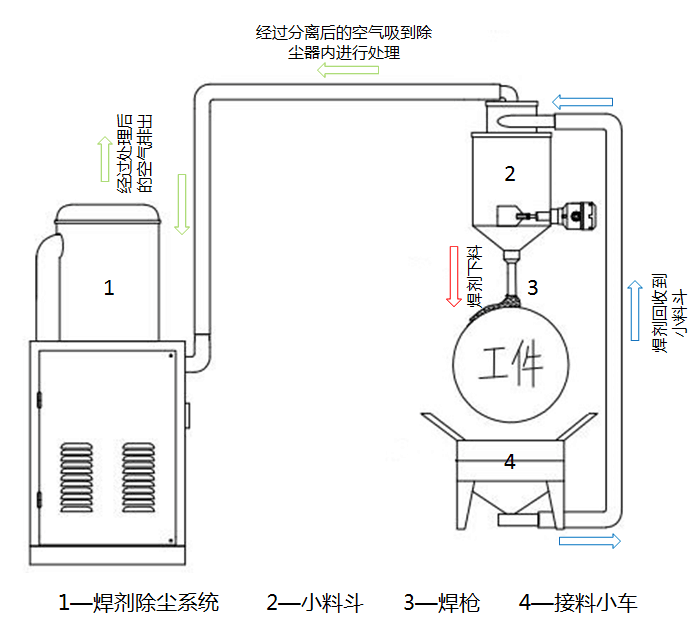

Graph 10 Welding flux feeding in recycling system main composition and working principal

Before welding, turn on flux hopper feeding in switch, flux then transported by feeding in hose to welding joint bevel arc area to cover welding area, which to protect welding arc.

When welding, remaining flux fall into downside flux collection trolley while welding slag is filtered at the same time. Meanwhile, flux storage level detection function is on, when flux in hopper is insufficient, then starting recycling to inhale flux into hopper, which realizes cyclic utilization in flux.

Dust and gas during recycling will be inhaled into dedusting system for processing after filtration.

This flux feeding recycling system avoids frequent flux feeding in and recycle manually, which saves time and ensures welding quality, improving pipe spool welding general efficiency. With trolley collecting welding flux and slag, it makes work site floor to be clean and reduces safety hazards. Also, the system has features of decent recycling effect, strong in working continuously, good dedusting function, etc, which guarantees effective welding flux dust and gas cleaning, reduces flux wastage, improving economic benefit.

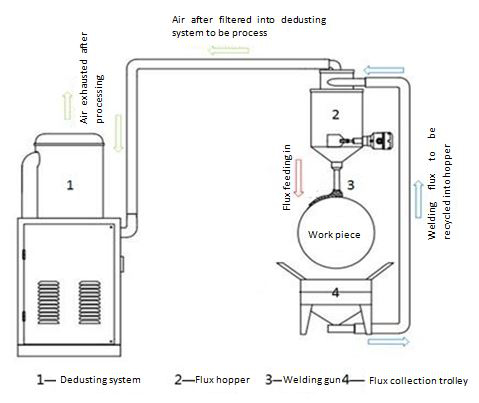

Graph 11 Welding flux feeding in recycling drawing

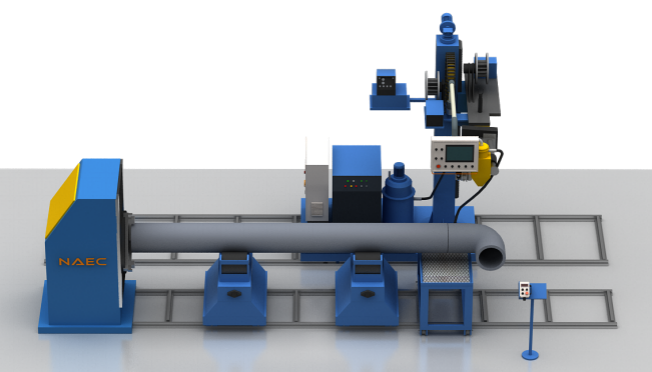

Graph 12 Welding flux feeding in recycling system

Scan the QR code to read on your phone

Relevant news

Address: No. 1 Zhongxing West Road, Lishui District, Nanjing, Jiangsu, China

Email:auto@autowelds.com

WeChat public number