News

Top Level Smart Robotic Welding System---NAEC New Broaden Business Scope!

- Categories:News

- Author:

- Origin:

- Time of issue:2021-04-02 10:05

- Views:

(Summary description)

Top Level Smart Robotic Welding System---NAEC New Broaden Business Scope!

(Summary description)

- Categories:News

- Author:

- Origin:

- Time of issue:2021-04-02 10:05

- Views:

In the past 20 years, NAEC dedicated to providing the customized lean fabrication one stop solutions and expert services:

Pipe Spool/Piping Lean Fabrication Solution

Storage Tank/Farm Construction Solution

Pressure Vessel/Offshore Platform/Offshore Tubular Fabrication Solution

Pipeline/Wind Tower Double Joining Solution for Pipeline Double Joining, Shell Double Joining etc.

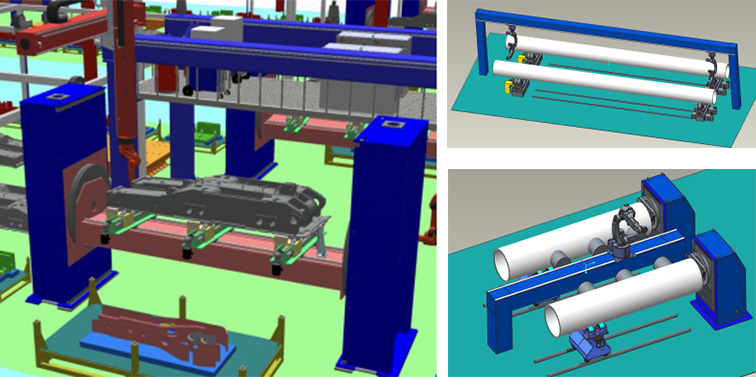

Since year 2020, NAEC broaden its business scope of Intelligent Lean Fabrication Solution which involving Robotic Welding System with flexible application for many projects, such as Excavator Manufacturing, Truck-mounted Crane, Crawler Crane, Pipe Spool Branch Saddle welding and the Heavy Equipment Manufacturing for LNG/LPG Truck Fabrication, Refrigeration Screw Chiller/Compressor, Boiler, Reaction Vessel, Pressure Vessel, Blast Furnace Manufacturing, etc.

Wide scope:

Main Advantages:

1.From hours to minutes

By adopting robotic welding system, such as pipe spool fabrication, production time goes from several man-hours to several minutes, production cost per pipe spool is drastically reduced, that to achieve small amount of manpower input even unman.

2.Stable and improved welding quality

When adopts robotic welding system, robots automatically follow the weld seam that the parameter of every welding seam is constant, which means the influence from manpower is very small, the welding quality is stable. The consistent welds without the need for rework.

3.Easy for Intelligent workshop upgrading

Adopting robotic welding system for intelligent upgrading is flexible for the implementation of intelligent workshop. Optimize production flow that all connected systems are centrally controlled, using logistic software, resulting in a highly efficient production flow.

Its excellent and diversified welding process is the premise for wide application with high efficiency and good performance!

Scan the QR code to read on your phone

Relevant news

Address: No. 1 Zhongxing West Road, Lishui District, Nanjing, Jiangsu, China

Email:auto@autowelds.com

WeChat public number