Products

-

Leading Products

-

Process Pipe Fabrication

-

Storage Tank Construction

-

Horizontal Shell Fabrication

-

Circumferential &Longitudinal Seam Welding Station

-

Gantry type outer seam welding station

-

Automatic outer seam cleaning and grinding station

-

Four dimensional alignment station

-

5-axis CNC Flame and Plasma Cutting & Profiling Machine

-

Changeable Radius Mid-Frequency Induction Preheating System Main character

-

-

-

Process Pipe Fabrication

-

Cutting machine

-

Pipe Cutting and Beveling All-in-one Machine

-

5-axis CNC Flame and Plasma Cutting & Profiling Machine

-

High Speed Band Cutting Machine

-

2-axis CNC Flame and Plasma Cutting & Profiling Machine

-

Movable Type 5-axis CNC Flame and Plasma Cutting & Profiling Machine

-

Movable Type high speed band saw Cutting Machine

-

-

Beveling machine

-

Conveyor system

-

Multifunctional fitting up machine

-

Automatic welding machine

-

Preheating device

-

-

Storage Tank Construction

-

Horizontal Shell Fabrication

-

Plate Sutting Machine

-

Plate milling machine

-

Welding Manipulator

-

Longitudinal Seam Welding Machine

-

Conveyor System

-

Circumferential seam welding machine

-

Circumferential/longitudinal seam automatic gouging machine

-

Preheating Machine

-

Four Dimension Fitting-up machine

-

Fitting up rotator

-

Welding rotator

-

Automatic longitudinal seam welding machine

-

Automatic circumferential seam welding machine

-

-

Intelligent Workshop

-

Intelligent Workshop Management System

-

Intelligent Logistic System

-

Aerial Work Platform

-

Welding Power Source

-

Spare Parts

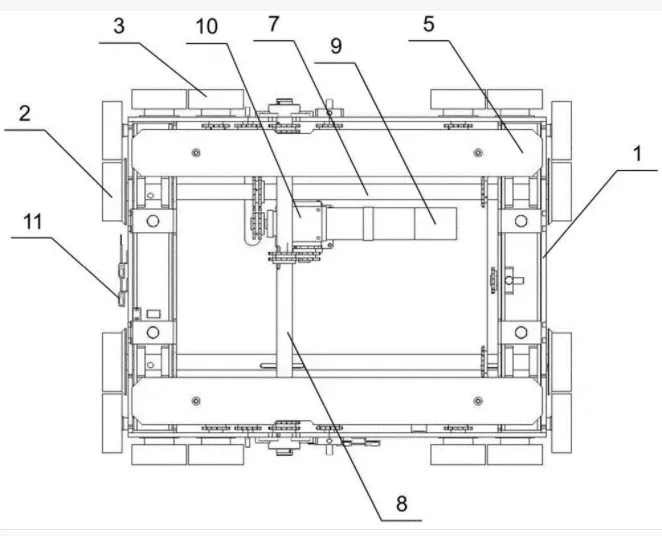

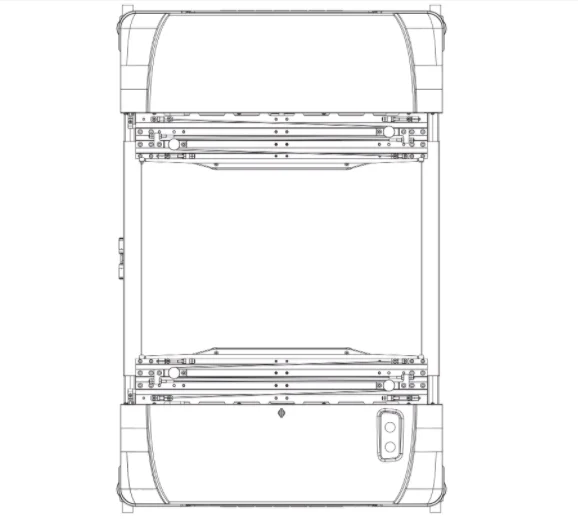

Automatic Racking Four Way Shuttle 4-Direction Robot For Racking Automated Storage System

Product Description

|

Item |

Specification |

|

Loading capacity |

1000kg |

|

Running speed |

0~120m/min |

|

Traveling mode |

Four-direction |

|

Rated duration time |

8h |

|

Application temperature |

-10~45℃ |

|

Noise |

<75dB |

Shuttle racking adopts shuttle cart as the main access equipment. The storage capacity of the system can reach 80%. The wireless remote controller of shuttle car can ensure the personal safety, and add fun to warehousing operation. The guide rail produced by special forming machine ensures the smooth operation of the system.

Our Advantages

Our Advantages

1 Achieve the highest density of storage, significantly reduce the cost of warehouse construction

2 Goods can be freely chosen First in first out or first in and then out

3 Realize that the drive-in racking does not need to drive in, and the efficiency of entering and discharging goods is high.

4 Seismic safety performance is much higher than drive in racking.

FAQ

1, What is MOQ limitation for rack system?

++ NO. But large purchase will bring competitive prices, 20FT container ( 10T~13T) is highly recommended, so that production can be better handled.

2, What is the lead time

++ As per 20FT container loading, manufacture time is about 10-15 days; Regarding some customized items 20-25 days will be covered.

3, What is payments methods you can accept?

++ T/T and L/C are welcomed.

4, How about your sample delivery?

++ Short section of uprights and beams can be provided free of charge. But the freight will be collected upon your duty.

5, What is warranty for your rack system?

++ All rack items will be warrantied against manufacture's defects.

++ To avoid any shortage or missing components, we will provide 1%~2% spare parts besides basic ones.

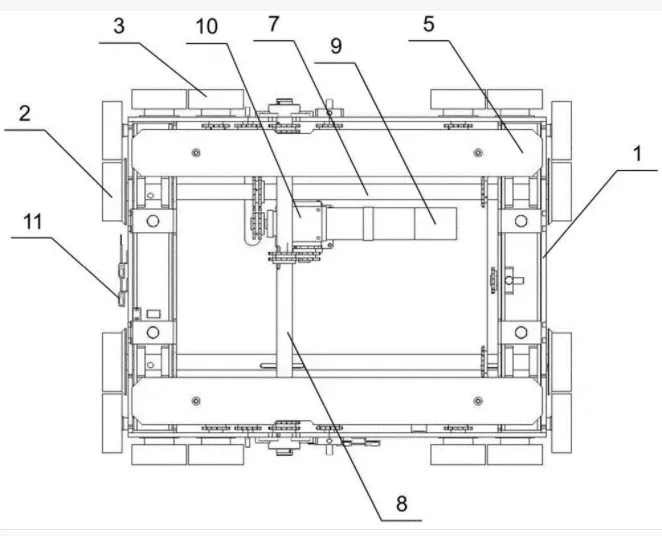

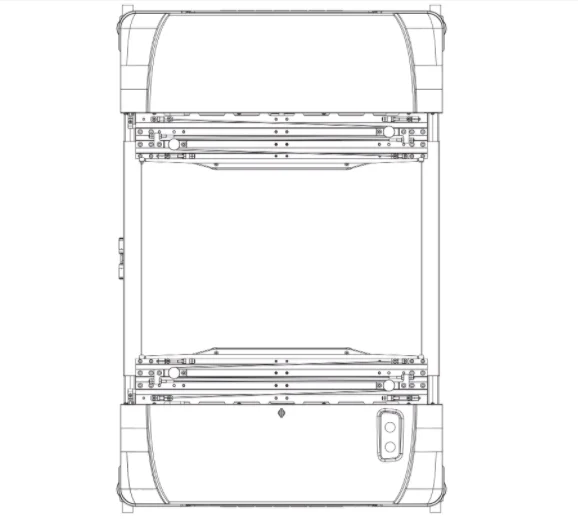

Automatic Racking Four Way Shuttle 4-Direction Robot For Racking Automated Storage System

Product Description

|

Item |

Specification |

|

Loading capacity |

1000kg |

|

Running speed |

0~120m/min |

|

Traveling mode |

Four-direction |

|

Rated duration time |

8h |

|

Application temperature |

-10~45℃ |

|

Noise |

<75dB |

Shuttle racking adopts shuttle cart as the main access equipment. The storage capacity of the system can reach 80%. The wireless remote controller of shuttle car can ensure the personal safety, and add fun to warehousing operation. The guide rail produced by special forming machine ensures the smooth operation of the system.

Our Advantages

Our Advantages

1 Achieve the highest density of storage, significantly reduce the cost of warehouse construction

2 Goods can be freely chosen First in first out or first in and then out

3 Realize that the drive-in racking does not need to drive in, and the efficiency of entering and discharging goods is high.

4 Seismic safety performance is much higher than drive in racking.

FAQ

1, What is MOQ limitation for rack system?

++ NO. But large purchase will bring competitive prices, 20FT container ( 10T~13T) is highly recommended, so that production can be better handled.

2, What is the lead time

++ As per 20FT container loading, manufacture time is about 10-15 days; Regarding some customized items 20-25 days will be covered.

3, What is payments methods you can accept?

++ T/T and L/C are welcomed.

4, How about your sample delivery?

++ Short section of uprights and beams can be provided free of charge. But the freight will be collected upon your duty.

5, What is warranty for your rack system?

++ All rack items will be warrantied against manufacture's defects.

++ To avoid any shortage or missing components, we will provide 1%~2% spare parts besides basic ones.

Related products

Address: No. 1 Zhongxing West Road, Lishui District, Nanjing, Jiangsu, China

Email:auto@autowelds.com

WeChat public number