Product Description

Aote is committed to solving the problem of traditional manual operation restricting the production capacity of enterprises, such as the recruitment and retention difficulties of special operations personnel such as welding and painting, which are particularly prominent, and the production efficiency is low. Through the application of intelligent manufacturing technology, Aote has launched the "no-sight-teaching + vision" intelligent welding program to reduce the demand for special operations and improve the proportion of professional and technical personnel. At the same time, it can increase production capacity by 1.5-3 times.

Relying on intelligent core equipment:

1. High-precision laser cutting machine, automatic CNC intersecting line cutting machine, high-precision plasma cutting machine, three-dimensional plasma fine cutting car and other cutting equipment, cutting accuracy within ±0.5mm, to ensure the pre-process parts of high-quality processing and rapid output;

2. Automatic press, automatic feeding CNC bending machine, CNC plane drilling machine, radial drilling machine, plate rolling machine and other automatic machining equipment, high-precision product processing, efficient output to ensure the intelligent logistics through.

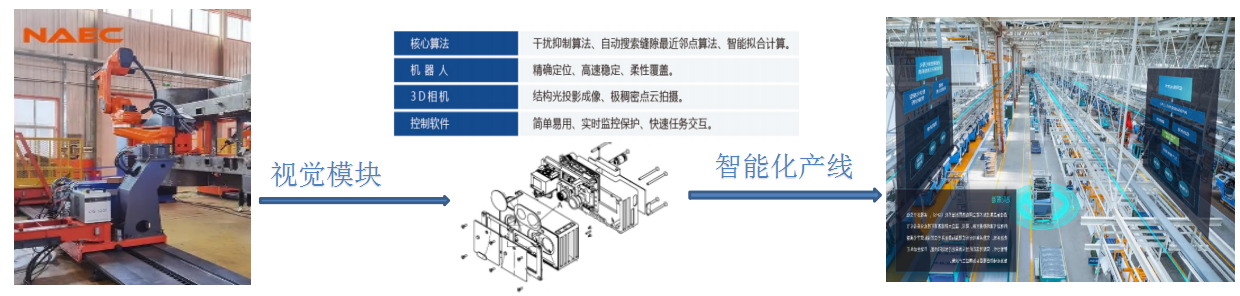

3. The welding robot is equipped with fine recognition technology, high-precision 3D modeling algorithm, 3D point cloud registration algorithm and 3D deviation correction algorithm. Structured light high precision imaging, complex scene compensation optimization. Advanced technologies for flexible task monitoring and scheduling and support for a wide range of part types.

Through these intelligent equipment, the combination of hardware and software to achieve dynamic management for the production and manufacturing process, the execution of predictive maintenance and improvement processes, that is, to achieve intelligent management and decision-making, to complete the smooth landing of intelligent steel production projects.

Solution

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

Address:No. 1, Zhongxing West Road, Lishui District, Nanjing City, Jiangsu Province

Copyright © Nanjing Autoweld Automation Co., Ltd. All Rights Reserved

Jiangsu Public Security Network Security Permit No. 32011502010584

Jiangsu Public Security Network Security Permit No. 32011502010584

Website Construction:www.300.cn Nanjing

Follow Us

Group Company

Group Company