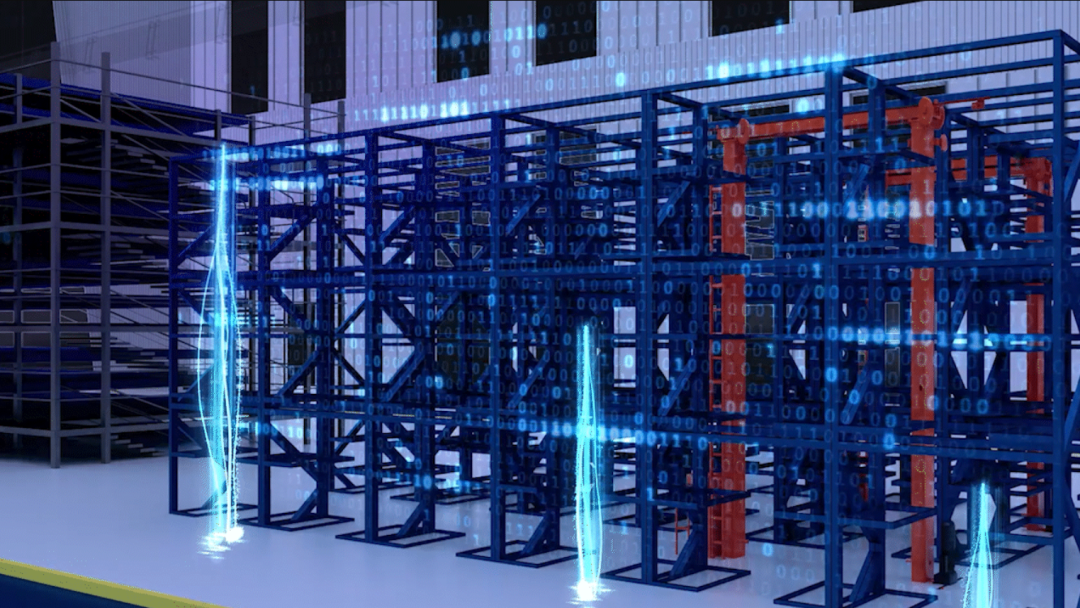

Project Case: Automatic Storage & Retrieval System (AS/RS) Solution for a Petrochemical Enterprise

2025-03-19

NAEC Intelligent Logistics

Intelligent warehousing and logistics systems significantly enhance inventory turnover efficiency, reduce operational costs, and minimize human exposure to hazardous environments. Additionally, they offer real-time data analysis, It plays a vital role in the supply chains of oil refineries, chemical plants, petrochemical manufacturers, and distribution/logistics companies.

Tailored to the unique warehousing needs of petrochemical enterprises, NAEC Intelligent Logistics integrates “Smart System + Intelligent Equipment” to deliver customized AS/RS solutions. These solutions optimize warehouse space, improve operational efficiency, and reduce costs, ensuring intelligent and lean management.

NAEC Intelligent Logistics

Automated AS/RS Solution

NAEC AS/RS Solution for a Petrochemical Enterprise

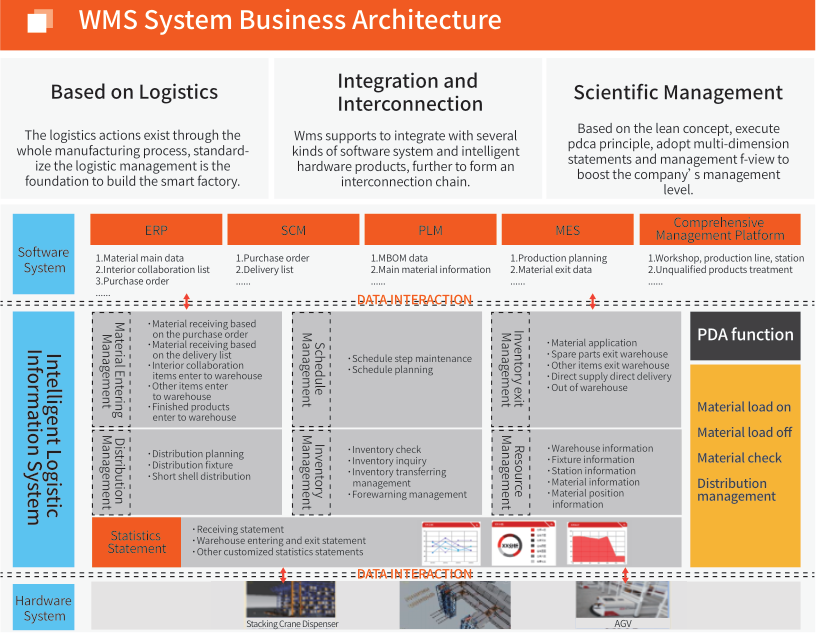

SMART+ Intelligent Logistics Information System

The project utilizes a Warehouse Management System (WMS) to enable intelligent inventory monitoring and control. The system integrates inbound, in-stock, and outbound operations with batch and real-time management, ensuring end-to-end tracking of warehouse activities and cost management while improving operational transparency.

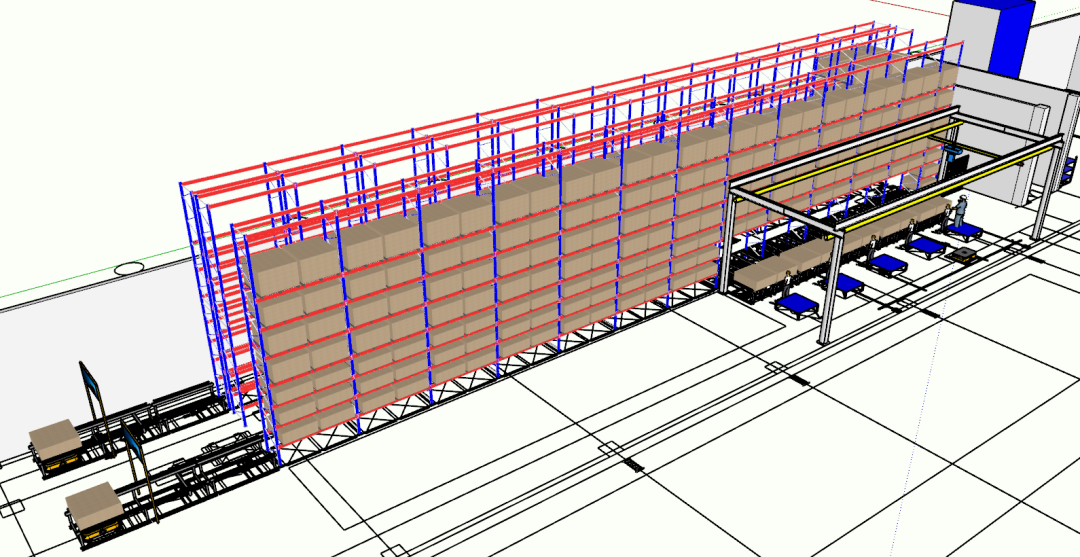

Automatic Storage & Retrieval System (AS/RS)with Stacker Cranes

The project utilizes an Automated Storage & Retrieval System (AS/RS) with stacker cranes for material storage, employing pallets as the storage medium. The design superiority of this automated pallet rack system with stacker cranes is evident in several aspects:

1.Maximized Storage Utilization – Optimized warehouse space allocation while avoiding equipment interference.

2.Seamless Material Flow – A front-end conveyor system enables automated inbound/outbound processes, online sorting, order picking, and automatic stacking of mother pallets.

3. Enhanced Safety Measures – The system is equipped with safety barriers, ensuring human-machine separation and minimizing risks.

Warehouse Parameters:

Load Unit: W1400×D1400×H1170mm / 1,000kg

Storage Type: Steel pallet

Rack Layout: 1 aisle, 4 rows, 9 columns, 4 levels

Total Storage Capacity: 288 pallet storage locations

WMS System

The WMS is centrally deployed for unified management across multiple warehouses. It supports hierarchical management, covering projects, disciplines, warehouses, storage zones, and bin locations. The system automates inventory tracking, data maintenance, stock management, reporting, and real-time dashboard visualization.

Intelligent Automatic Storage & Retrieval System (AS/RS) represent a major trend in the future of warehousing. With advancements in artificial intelligence(AI), big data, and the Internet of Things (IoT), the demand for intelligent warehouse management is growing rapidly among enterprises. NAEC Intelligent Logistics has extensive experience in implementing Intelligent Automatic Storage & Retrieval System solutions, helps enterprises build smart storage systems, improve productivity, and secure a competitive edge in their industry.

END

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

Address:No. 1, Zhongxing West Road, Lishui District, Nanjing City, Jiangsu Province

Copyright © Nanjing Autoweld Automation Co., Ltd. All Rights Reserved

Jiangsu Public Security Network Security Permit No. 32011502010584

Jiangsu Public Security Network Security Permit No. 32011502010584

Follow Us

Group Company

Group Company