Application of Automated Storage and Retrieval Systems (AS/RS) inShipyard Pipe Fittings Management

2025-05-07

NAEC Intelligent Logistics

Shipbuilding is a quintessential heavy equipment industry, and its pipe fittings management has long been plagued by challenges such as "a wide variety of types, complex specifications, frequent turnover, and stringent safety requirements." Traditional warehousing models rely heavily on manual sorting and paper-based record-keeping, which are inefficient and prone to errors, omissions, and delays that can compromise project timelines and even create safety risks. With the global surge in "intelligent manufacturing," shipyards urgently need to adopt technological innovations to achieve precise, efficient, and traceable warehouse management.

The Automated Storage and Retrieval System (AS/RS), as a core component of smart factories, provides an all-in-one solution for pipe fittings management at shipyards through human-machine collaboration, intelligent scheduling, and full-process digitalization. This article analyzes how AS/RS restructures the logistics system of a large shipyard project, driving the shipbuilding industry toward high-quality development.

Overall Planning:

01.Lean Design + Ergonomics: Dual Improvement in Safety and Efficiency

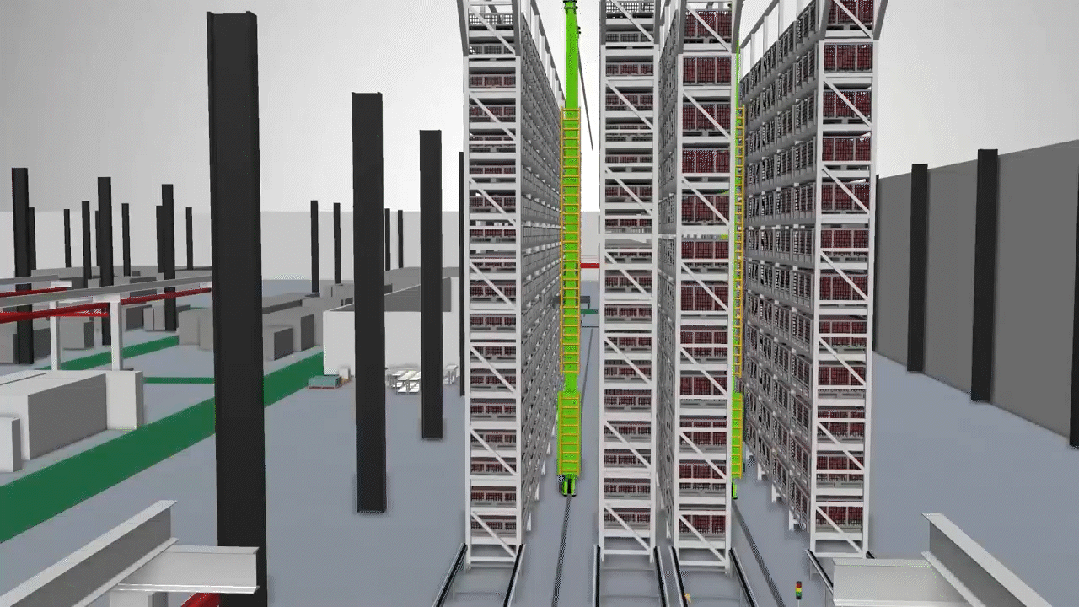

Project Overview:This shipbuilding warehouse primarily stores flanges, elbows, and other pipe fittings. The warehouse consists of four double-reach pallet stacker cranes, pre-storage conveyor lines, and other components.

The two AS/RS areas cover a total usable area of 1,245.8 square meters, with the following functional zones planned: pre-storage conveyor line area, AS/RS stacker crane and shelving area, inbound and outbound buffer zones, material worker rest areas, incoming goods inspection areas, and material staging areas. The multi-functional zoning and the use of beam-type shelving for AS/RS enable automatic material entry and exit, improving storage efficiency, capacity, and operational performance.

Safety Guardrails and Intelligent Isolation:All automated equipment is surrounded by safety guardrails for isolation. Human-machine interaction workstations ensure that equipment operation paths do not overlap with manual work areas. Interaction channels are marked with prominent safety signs, and mobile equipment is equipped with multiple safety protection mechanisms.

Lean Design Planning:For small-item repackaging tasks, both before and after operations, material bins are handled using an online process to save labor. In the picking area, the PTL (Pick-to-Light) system is used for intelligent guidance, reducing manual searching and lowering task difficulty. Functional areas are tightly arranged based on operational relevance, ensuring optimal movement routes for both humans and equipment.

Green Manufacturing and Energy Efficiency:The design emphasizes quiet and eco-friendly operations. All motorized equipment and noise control meet the standards of the "Industrial Enterprise Noise Control Design Standards", enhancing employee focus and satisfaction while balancing efficiency and comfort.

Intelligent Equipment:

02.Core Technologies Empowering Efficient Operations

►►►Pallet Stacker AS/RS System

The advantages of the stacker AS/RS design in this project include:

1. Maximizing storage space without interference between equipment;

2. The front-end conveyor system enables AGV automatic inbound and outbound material handling, as well as picking and returning to the warehouse;

3. Installing safety guardrails around the AS/RS to ensure human-machine separation and prevent accidents.

►►►

NAEC Intelligent AGV System

NAEC’s self-developed unmanned intelligent AGV series uses laser SLAM hybrid navigation technology, including forklift AGV, towing AGV, and various customized AGV. These solutions cater to specific customer scenarios and automation upgrade needs.

Based on lean thinking and holistic planning, the integration of information systems, automated equipment, big data, and IoT technologies enhances the intelligent analysis, decision-making, and execution capabilities of the warehousing system. This boosts operational efficiency and achieves modern logistics.

A production-oriented warehousing and logistics system boundary is established, with the WMS system at its core managing inbound/outbound operations, inventory, data, and order tasks. The LES system focuses on order preprocessing, logistics execution, line-side management, container management, and LCS strategies for route planning, equipment control, and monitoring. This integration realizes informatization and automation of warehousing and logistics, achieving seamless connectivity across all processes and scenarios.

Industry Benchmarks:

03.Cross-Industry Practices Validate Technical Strength

In addition to shipyard projects, this solution has been successfully applied in multiple industries, validating its high adaptability and scalability:

►►►

Case Study: Pharmaceutical AS/RS

With 8 aisles and 5000 pallet positions, this warehouse integrates pallet conveyors, box conveyors, RGV high-speed transport, robotic palletizing, empty pallet stacking, and online picking. It interfaces with WMS, ERP, MES, WCS, LES, and other information systems to address the storage challenges of pipe materials.

►►►

Case Study: Electrical Industry AS/RS

A 24-meter high rack warehouse with AGV conveyors, interfacing with WMS, MES, WCS, and ERP information systems, enables "smart warehousing" operations with 30,000 pallet positions.

►►►

Case Study: Pipe Material-Specific AS/RS

Configured with a cantilever rack system, conveyors, and heavy-duty AGVs, and integrated with MES and production line control systems, it automates pipe material storage and retrieval, improving accuracy and warehouse space utilization.

THE END

The Automated Storage and Retrieval System (AS/RS) is a critical link in shipyards' journey toward "smart shipbuilding." Through human-machine collaboration, intelligent scheduling, and green, low-carbon Three-dimensional Solution, pipe fittings management has transitioned from "coarse storage" to "full lifecycle control." This transformation has become the core engine for cost reduction, efficiency improvement, safety assurance, and intelligent management in the shipbuilding industry.

Recommended News

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

Address:No. 1, Zhongxing West Road, Lishui District, Nanjing City, Jiangsu Province

Copyright © Nanjing Autoweld Automation Co., Ltd. All Rights Reserved

Jiangsu Public Security Network Security Permit No. 32011502010584

Jiangsu Public Security Network Security Permit No. 32011502010584

Website Construction:www.300.cn Nanjing

Follow Us

Group Company

Group Company