Break Bottlenecks in Metal Manufacturing with NAEC Digital Twin

2025-07-18

NAEC Intelligent Digital

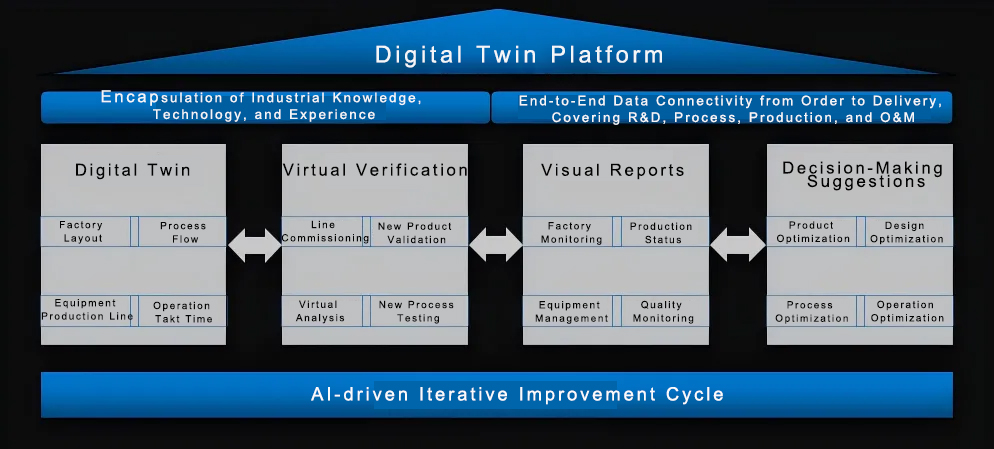

NAEC Digital Twin Platform

Order delays, high costs, frequent quality issues, and low automation...

Traditional production models—characterized by structural complexity, small batches, high discreteness, and heavy labor reliance—are increasingly challenged.

Leveraging deep industry insights and years of experience in automated production lines and simulation solutions for the metal engineering industry, NAEC Intelligent Digital has developed the Digital Twin Platform—a solution that goes far beyond visualization. It integrates deeply with AI to enable full-process virtual mapping, simulation optimization, and real-time control from design to operation and maintenance—making your production visible, controllable, and manageable.

NAEC Digital Twin Platform:

A New Path for Metal Engineering Production

Nanjing Auto Intelligent Digital Technology Co.,Ltd

The NAEC Digital Twin Platform provides a clear and efficient business pathway, delivering comprehensive intelligent solutions for metal engineering production.

NAEC 01 — Building the Digital Twin: Creating a “Virtual Replica” of Your Factory

Want a real-time virtual representation of your physical factory? NAEC’s Digital Twin Platform makes it possible. Define factory units by importing digital models or selecting intelligent components from a rich library. Then, combine them using layout and process design functions to assemble these elements into the factory's Digital Twin.

The simulation platform allows fast digital twin creation via 3D layout and process flow design tools. It also offers AI-powered layout generation—by building a model knowledge base and integrating AI Agents, users can generate line layouts simply through voice commands.This virtual replica mirrors the real-world production process in real time and serves as a solid foundation for advanced production management.

NAEC 02 Virtual Simulation & Verification: Early Detection, Optimized Solutions

With the Digital Twin, conduct virtual simulation and verification. During the product R&D and design phase, validate manufacturing feasibility, production line accessibility, tooling design rationality, and motion path optimization. The platform's AI Automatic Path Planning function automatically generates the optimal execution path between given start and end points and can export the optimal path program.

By simulating and optimizing cycle times, identify and resolve product design issues early, reducing costs while optimizing the best production plan. It's like a comprehensive "dress rehearsal" before actual production, solving potential problems in advance.

NAEC 03 — Virtual Commissioning: Shorter Lead Time, Lower Risk

Worried about long commissioning cycles and high risks?NAEC Digital Twin Platform enables virtual commissioning as early as the design phase.Its mechatronic design approach allows for early-stage validation of production processes (e.g., PLCs and robotic systems).

Using OPC DA and OPC UA servers, the platform provides standardized interfaces for efficient data communication between upper-level systems and physical PLCs.

By importing motion programs and trajectories into the twin platform, optimized data is then exported to the physical site, significantly shortening on-site commissioning cycles, reducing commissioning risks, and making production preparation more efficient.

NAEC 04 — Real-Time Control: Remote Management & Bidirectional Synchronization

The platform employs bidirectional software-driven control to enable remote factory management.

Drive 1: Real-world data collected from the field feeds the digital twin, keeping virtual equipment actions in sync.

Drive 2: Controlling the virtual equipment drives the actions of real-world machines.

This means real-time synchronization of data, motion, environment, and energy between the digital twin and the actual factory—supporting remote control, remote parameter optimization, and remote operations, breaking through spatial and temporal boundaries in factory management.

NAEC 05 — Multi-Terminal Access: Factory Management Anytime, Anywhere

Using low-code platform development for lightweight deployment, the Digital Twin Factory can be directly published to mobile devices, tablets, VR/AR headsets, Vision Pro, and other endpoints. This allows real-time spatial monitoring and management of the digital factory anytime, anywhere, using these devices.

Whether in the office, traveling, or on the production floor, easily grasp the factory's real-time status for more flexible and efficient management.

NAEC Digital Twin Platform Case Studies

Nanjing Auto Intelligent Digital Technology Co.,Ltd

NAEC

Digital Twin for Construction Machinery

Intelligent Assembly + AI Applications

NAEC planned a fully automated tire assembly and tightening unmanned workstation for a leading construction machinery manufacturer. Deeply integrating robotic handling, AI industrial vision recognition, automated logistics tracking, and real-time Digital Twin interconnectivity, it achieved the entire tire assembly process: automatic feeding, grasping, installation, and tightening.

NAEC

Factory Digital Twin Case in Metal Engineering

A Digital Twin based on a welding production line, achieving real-time synchronization of data from equipment, production lines, logistics, warehousing, and factory status (operational energy consumption).

NAEC

Digital Twin + IMIS + AI Application Case

A domestic prefabricated building manufacturer invested approximately 4 million yuan to build an intelligent production and monitoring system for a new workshop, simultaneously implementing an intelligent manufacturing system combining Digital Twin, IMIS (Intelligent Manufacturing Information System), and AI. This achieved intelligent production across all lines and real-time monitoring of product qualification rates.

The project covered work order production, production process monitoring, material identification, robot control, and data acquisition modules. It managed and monitored equipment/facilities on the line, evaluated line control system performance, aimed for maximum equipment utilization and rational production scheduling, and provided valuable decision-making information to management departments.

NAEC’s Digital Twin Platform supports end-to-end simulation and integration, including private, customized deployment, and solutions tailored to various levels of digital twin maturity.

With seamless virtual-real fusion, we help enterprises boost efficiency, ease management, and lower costs.

Recommended News

Group Company

Group Company

Jiangsu Public Security Network Security Permit No. 32011502010584

Jiangsu Public Security Network Security Permit No. 32011502010584