Industrial Production Line Digital Twin Solution — Full-Process Intelligent Management

2025-09-24

NAEC Intelligent Digital

As Industry 4.0 reshapes global manufacturing, many traditional enterprises face challenges such as non-transparent processes, stagnant efficiency, and high management costs. Digital Twin technology is emerging as a core engine to accelerate digital transformation in manufacturing.

NAEC Intelligent Digital’s Industrial Production-Line Digital Twin Solution, based on a “1+4+N” architecture, lays the foundation for a genuine “Future Factory”:

✅ “1” Smart Brain: An integrated command and data center for holistic monitoring and intelligent decision-making.

✅ “4” Core Platforms: Digital Twin, IoT, Big Data Analytics, and AI — four engines driving synergy and innovation.

✅ “N” Application Scenarios: Covering production processes, equipment management, workforce scheduling, energy optimization, and more — flexible, scalable, and adaptive.

Workshop & Production-Line Applications

Visible Intelligent Transformation

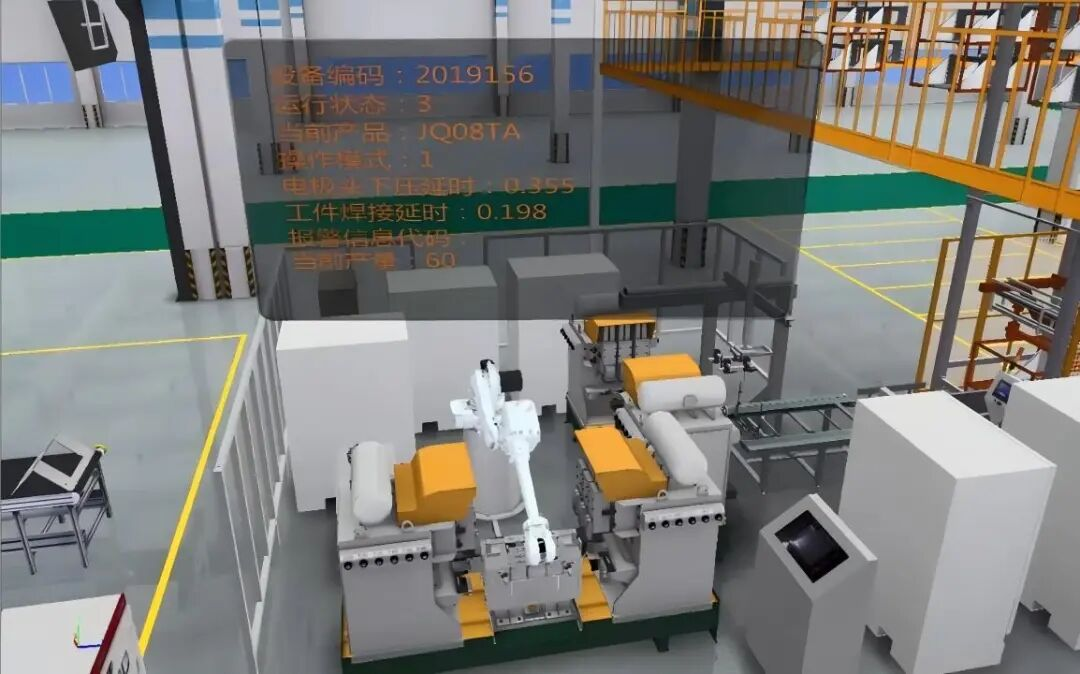

Workshop/Production Line-Level — Visualized Production Processes

Bid farewell to paper-based work instructions. Through high-precision 3D modeling and Unity engine rendering, dynamic visualization of entire production line processes is achieved. Both process engineers and operators can access real-time production data and process animations from multiple perspectives, ensuring clarity and ease of use.

Workshop/Production Line-Level — Batch/Process Traceability

The system supports 3D animation playback of the entire production process, enabling end-to-end traceability from raw material suppliers to finished product shipments. Key material batch positioning, product quality tracking, and highlighted abnormal links make quality control more precise and transparent than ever.

Workshop/Production Line-Level — Real-Time Production Data

By integrating data from MES, WMS, and other systems, the digital twin platform displays key metrics such as equipment status, personnel efficiency, and energy consumption indicators in real time. Abnormal events trigger automated tiered alerts, and production efficiency losses are quantified for rapid response and optimization.

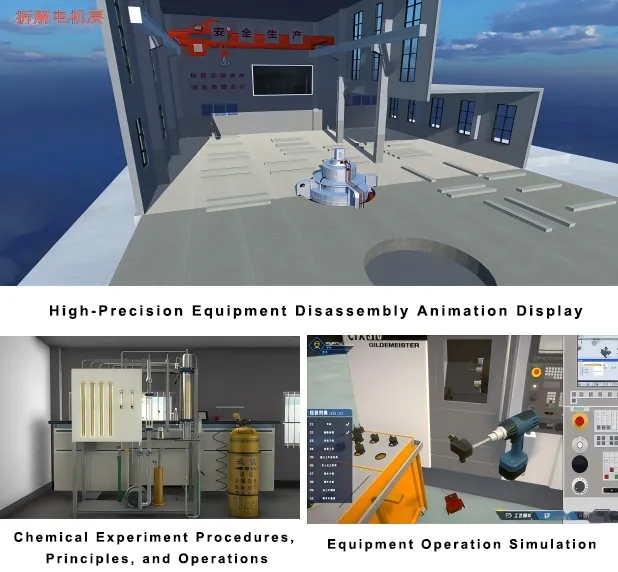

Workshop/Production Line-Level — 3D Work Instructions

Leveraging VR/AR technology, abstract operational procedures and safety protocols are transformed into visual and interactive virtual scenarios. Employees can simulate operations in virtual production lines, significantly reducing training costs while improving training effectiveness and operational standardization.

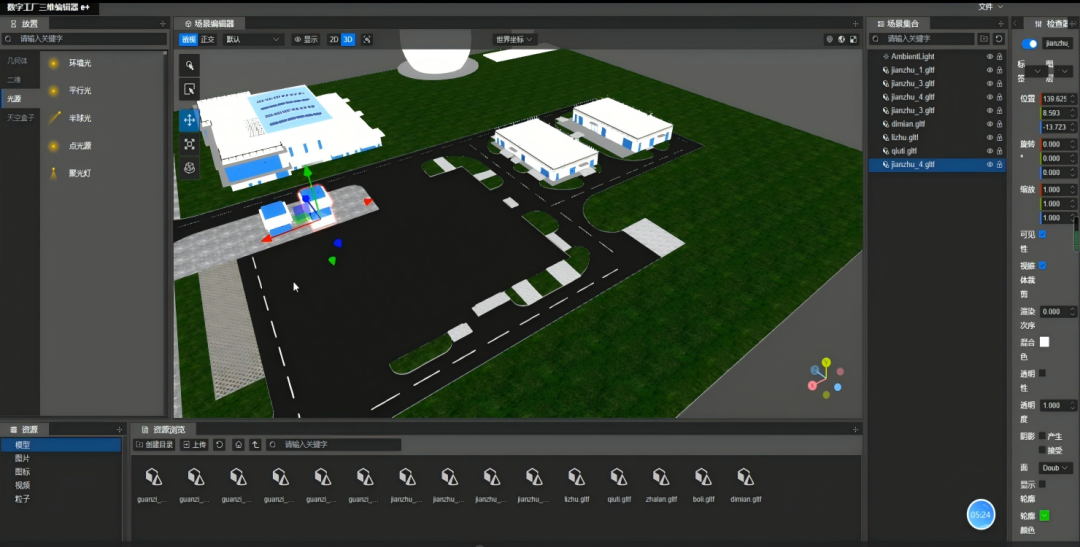

Workshop/Production Line-Level — Smart Production Line Design and Spare Parts Management

During the planning phase of new production lines, digital twin technology simulates equipment layout, AGV routes, and material flow to identify and mitigate design risks in advance. The system also dynamically tracks spare parts consumption and automatically updates inventory needs, enabling lean management.

Workshop/Production Line-Level — Production Efficiency Coordination

Using high-precision positioning technology, the system monitors personnel locations and work status in real time. Tasks are automatically assigned to workstations, and production progress is dynamically updated, greatly enhancing personnel scheduling efficiency and order delivery capabilities.

Typical Cases

Large Enterprise Cable Data Center

By integrating Digital Twin, BIM, GIS, IoT, and Big Data, NAEC Intelligent Digital built a unified model covering production, office, management, operations, and services — realizing element-level, full-process visualization and intelligent management.

Typical Cases

Smart Factory Visualization Platform

By leveraging IoT, Digital Twin, and equipment monitoring, the platform improves production information management and services. It enables process visibility from production to sales, enhances controllability, reduces manual intervention, ensures accurate data collection, supports optimized scheduling, and controls production progress — achieving personalized manufacturing, flexible production, proactive services, and intelligent decision-making.

Recommended News

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

Address:No. 1, Zhongxing West Road, Lishui District, Nanjing City, Jiangsu Province

Copyright © Nanjing Autoweld Automation Co., Ltd. All Rights Reserved

Jiangsu Public Security Network Security Permit No. 32011502010584

Jiangsu Public Security Network Security Permit No. 32011502010584

Website Construction:www.300.cn Nanjing

Follow Us

Group Company

Group Company