Innovation Breakthrough! NAEC Builds High-Efficiency Lean Pipe Spool Fabrication Production Line for Nuclear Power Project

2025-08-28

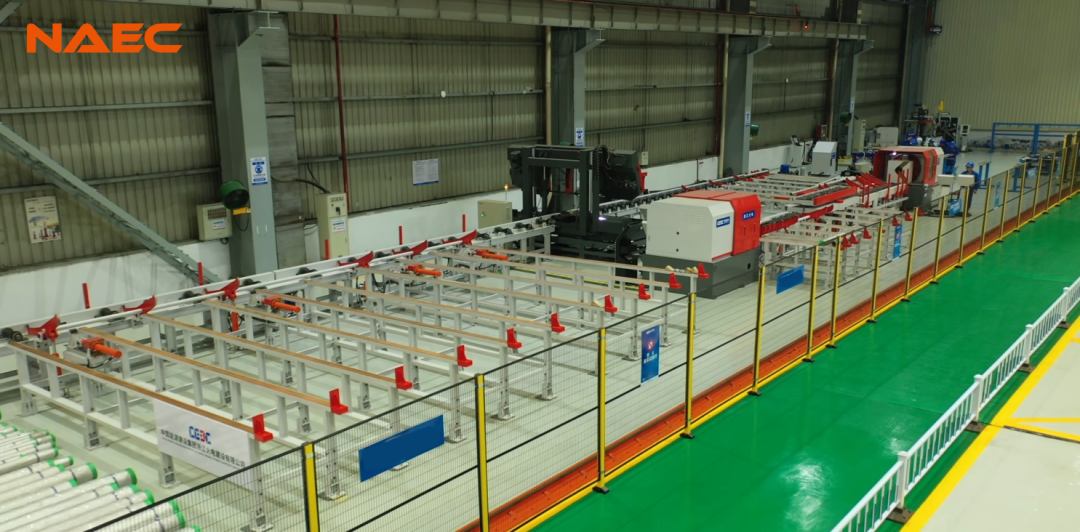

In nuclear power construction, enhancing the intelligence and efficiency of the pipe spool fabrication process is of paramount importance. With nearly 30 years of industry service experience and proven capabilities in implementing intelligent construction solutions, NAEC has developed a tailored lean manufacturing solution for the pipe spool fabrication production line of a major domestic nuclear power company, following in-depth research and evaluation.

Through its self-developed production line control system and intelligent gantry coordination, NAEC has achieved fully unmanned operation in the cutting area of the 2–8 inch carbon steel/stainless steel pipe spool fabrication production line. The intelligent logistics system delivers materials precisely to designated workstations, ensuring smooth and efficient production flow.

NAEC

01 Scientific Line Layout: Demand-Oriented, Optimized Efficiency

The planned fully digitalized intelligent production line covers raw material buffering, cutting, beveling, grinding, automatic fit-up, and intelligent logistics. The overall layout is streamlined, transportation is efficient, and production continuity and stability are fully guaranteed.

NAEC

02 Intelligent Control Hub: Flexible, Efficient, Cost-Reducing

The line is equipped with a centralized control workstation, allowing both independent station operation and system interconnection. Production tasks can be flexibly assigned through MES system automation or Excel import, enabling labeling, cutting, beveling, and grinding tasks to be dispatched with ease—boosting productivity while reducing material cost and waste.

NAEC

03 Core Process Equipment: Precision, Stability, Reliability

Equipped with circular saws, beveling machines, grinding stations, integrated fit-up, and integrated welding stations, the line ensures high-quality processing with low material loss. Easy to install and operate, it delivers over 40% improvement in single-pipe operation efficiency.

NAEC

04 Safety and Reliability with Continuous Upgradability

The equipment is safe and reliable, with core electrical components sourced from globally renowned brands such as Siemens and Inovance, ensuring stability and durability. Designed for long-duration high-efficiency operation (target: 1,000+ hours without failure), the line also features expandable interfaces and modular upgrades, laying a solid foundation for future functionality enhancements.

The high-efficiency lean pipe spool fabrication production line developed by NAEC Group for nuclear power projects has achieved fully unmanned operations and scientific planning, providing strong support for the long-term development of the production line. This breakthrough has significantly improved efficiency, reduced costs, and enhanced quality.

Recommended News

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

Address:No. 1, Zhongxing West Road, Lishui District, Nanjing City, Jiangsu Province

Copyright © Nanjing Autoweld Automation Co., Ltd. All Rights Reserved

Jiangsu Public Security Network Security Permit No. 32011502010584

Jiangsu Public Security Network Security Permit No. 32011502010584

Website Construction:www.300.cn Nanjing

Follow Us

Group Company

Group Company