NAEC Intelligent Production Line Case | Wheel Press Circumferential Seam Digital Twin

2025-08-22

ONE

Project Overview

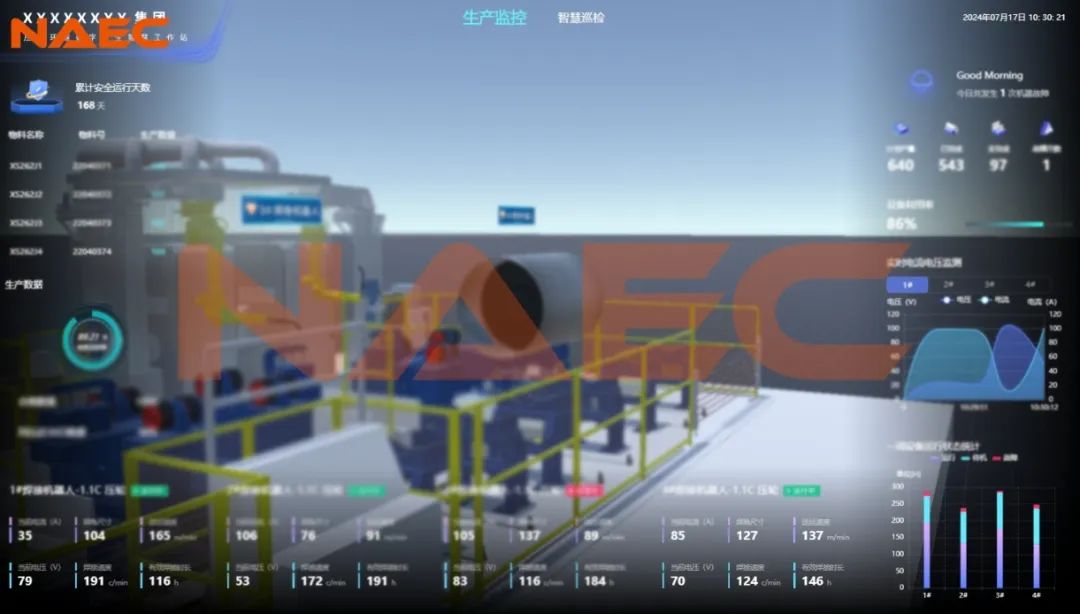

NAEC developed the “Wheel Press Circumferential Seam Digital Twin Smart Production Line Project” for a heavy industry group. As a key project in the group’s digital transformation, it connects the MES and LES systems, integrating upstream and downstream processes to create a fully unmanned digital production line.

The project features an intelligent dashboard with highly integrated video streams, 360° all-around monitoring, and a live digital twin that mirrors the physical environment. This delivers an immersive smart manufacturing experience.

NAEC

Digital Twin Production Line Dashboard / NAEC /

Focusing on the core needs of the project, NAEC implemented digital-physical integration of the wheel press circumferential seam production line based on digital twin technology. Leveraging its strong expertise in digital twin implementation and platform integration, NAEC provided robust technical support to ensure the successful construction of this smart production line.

The project was designed to achieve specific production capacity goals: each shift (7.5 hours) processes no fewer than 25 wheel press units per day. Typical welding parameters are preset, production rhythm is calculated, and the required actual capacity is provided.

NAEC

Application Highlights of Digital Twin Technology in Intelligent Production Lines

The application of digital twin technology in smart workstation scheduling systems marks a key step for lean manufacturing toward intelligence and efficiency. Through a highly integrated 3D visualization platform, it enables comprehensive, real-time mapping and monitoring of physical structures, production processes, equipment status, and business data.

NAEC

Global Situation Awareness / NAEC /

Managers gain a clear, intuitive, and three-dimensional view of workstation operations, including production progress, equipment layout, and task status—achieving a comprehensive grasp of overall operations.

NAEC

Transparent Production Management / NAEC /

3D simulation of key equipment, such as welding robots and wheel press seam robots, not only showcases their physical structure but also simulates real production processes, helping managers clearly understand every detail and optimize layouts and workflows.

NAEC

Real-Time Equipment Health Monitoring

By integrating live data such as current, voltage, and fault signals with intelligent analytics, the system can predict potential issues, reduce unplanned downtime, and improve equipment utilization and overall efficiency.

NAEC

Intelligent Decision Support

When encountering production anomalies or equipment failures, the digital twin system quickly locates problems and analyzes their impact, supporting managers in making fast, effective decisions to minimize downtime and losses.

NAEC

Data-Driven Continuous Improvement

By continuously collecting and analyzing production data, the digital twin system provides valuable insights for lean manufacturing, helping enterprises optimize processes, improve product quality, reduce costs, and drive ongoing innovation.

With its powerful 3D visualization capabilities and intelligent management functions, NAEC’s Digital Twin Smart Workstation Scheduling System accurately mirrors the physical environment, simulates equipment operations, integrates real-time data, and provides early warnings for potential issues.This enables managers to make rapid decisions, optimize production processes, and enhance both efficiency and safety—fully empowering industrial enterprises in their journey of digital transformation and smart development.

Recommended News

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

Address:No. 1, Zhongxing West Road, Lishui District, Nanjing City, Jiangsu Province

Copyright © Nanjing Autoweld Automation Co., Ltd. All Rights Reserved

Jiangsu Public Security Network Security Permit No. 32011502010584

Jiangsu Public Security Network Security Permit No. 32011502010584

Website Construction:www.300.cn Nanjing

Follow Us

Group Company

Group Company