News

NAEC Lean Pipe Spool Fabrication Management System

- Categories:News

- Author:

- Origin:

- Time of issue:2024-03-01 13:18

- Views:

(Summary description)

NAEC Lean Pipe Spool Fabrication Management System

(Summary description)

- Categories:News

- Author:

- Origin:

- Time of issue:2024-03-01 13:18

- Views:

NAEC Lean Pipe Spool Fabrication Management System, tailored for the pipeline construction industry, The management system offers fine-grained production control throughout the entire lifecycle of pipe spool fabrication, including factory prefabrication, on-site prefabrication, and on-site construction. This system ensures efficient production, meets project deadlines, and supports multiple languages, making it globally accessible.

It establishes five collaborative systems for manufacturing processes: planning collaboration, process collaboration, inventory collaboration, equipment collaboration, and big data operational analysis. This addresses issues such as delayed production delivery, inventory backlog, low production efficiency, low yield rates, and lack of transparency in the production process. Consequently, it enhances production efficiency, reduces costs, and enables data-driven manufacturing.

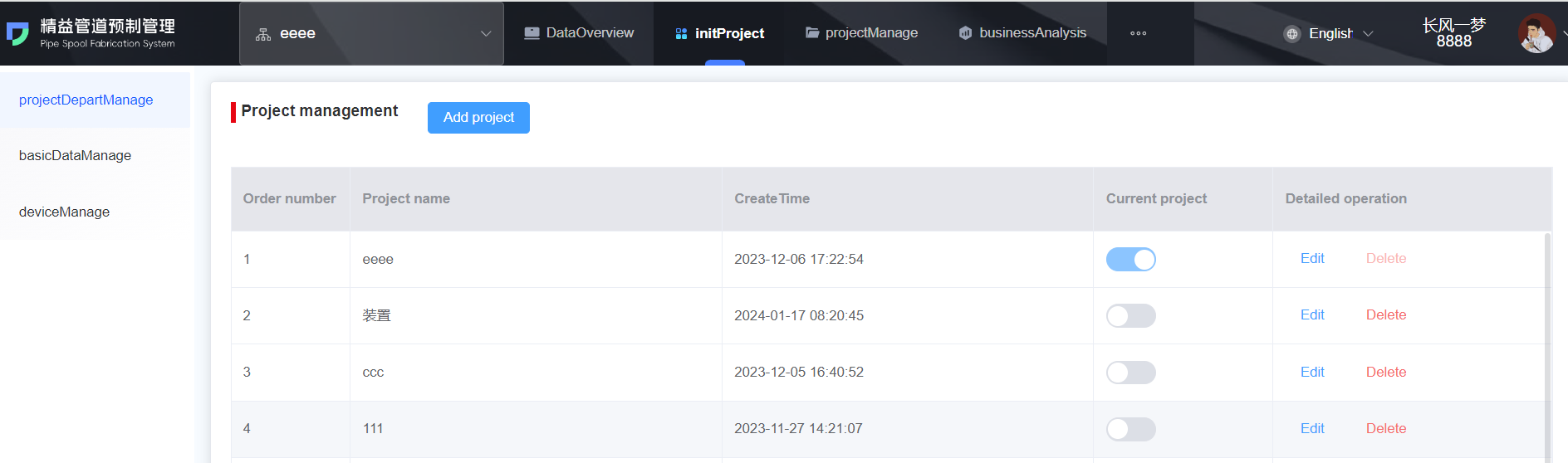

01 Project Initiation

NAEC Lean Pipe Spool Fabrication System, grounded in lean production concepts and integrated with Internet of Things (IoT) and big data technologies, aligns the entire business process. It utilizes factory modeling to establish a set of models for production, products, and process-related data within the system, providing fundamental data support for future business modules. This helps enterprises conduct production management based on their unique models, enhancing their management capabilities and core competitiveness.

● Industry Pain Points

01 High info volume & numerous planning points.

02 Poor basic info management.

03 Varying requirements for managing multiple projects.

● Highlights of the Plan

01 Project division and individual initiation

02 Multi-dimensional management of basic data

03 Simultaneous establishment for multiple factories and projects

04 Flexible & reliable production information configuration

Device Management

● Industry Pain Points

01 Multiple types and models of production equipment on site

02 Inability to quantify equipment production capacity

03 Lack of real-time control over equipment status

04 Delayed equipment malfunction alarms

● Highlights of the Plan

01 Support for multiple types of equipment integration

02 Tagging of equipment production capacity

03 Real-time monitoring of equipment status

04 Triggering early warnings for equipment malfunctions

02 Project Management

NAEC Lean Pipe Spool Fabrication System,collects and integrates multiple constraints in production management, reshapes them into a scheduling philosophy guided by Otto Lean production principles, and maximizes its adaptability to the diverse production mode needs of customers. It is suitable for generating complex production plans under various scenarios.

Project Planning Management

● Industry Pain Points

01 Scheduling highly reliant on manual labor

02 Slow and inefficient updates to production tasks

03 Frequent insertion of additional or urgent orders

04 Difficulty in maximizing overall production capacity

● Highlights of the Plan

01 Advanced Scheduling for Efficiency Improvement

02 Task Optimization with Regular Updates

03 Task Prioritization for Scheduling

04 Balancing Resource Loads

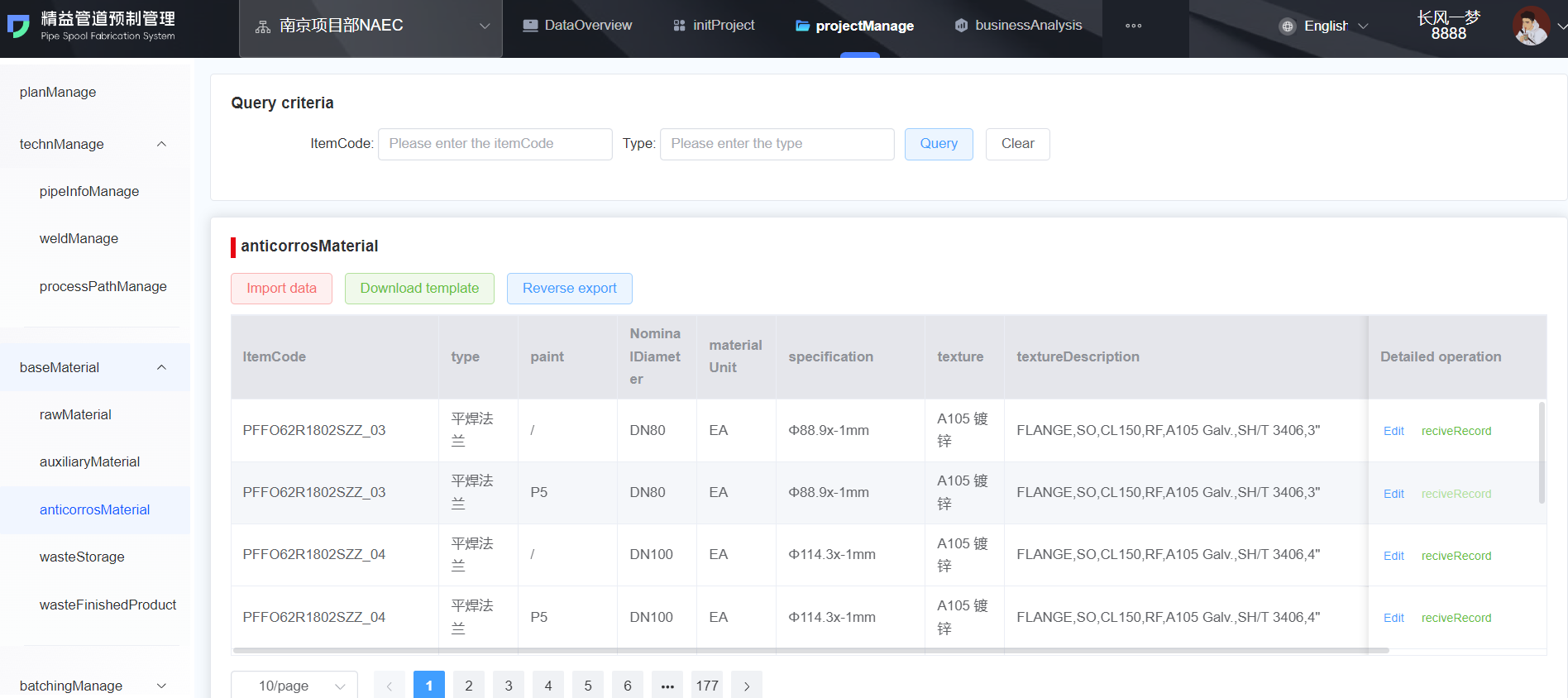

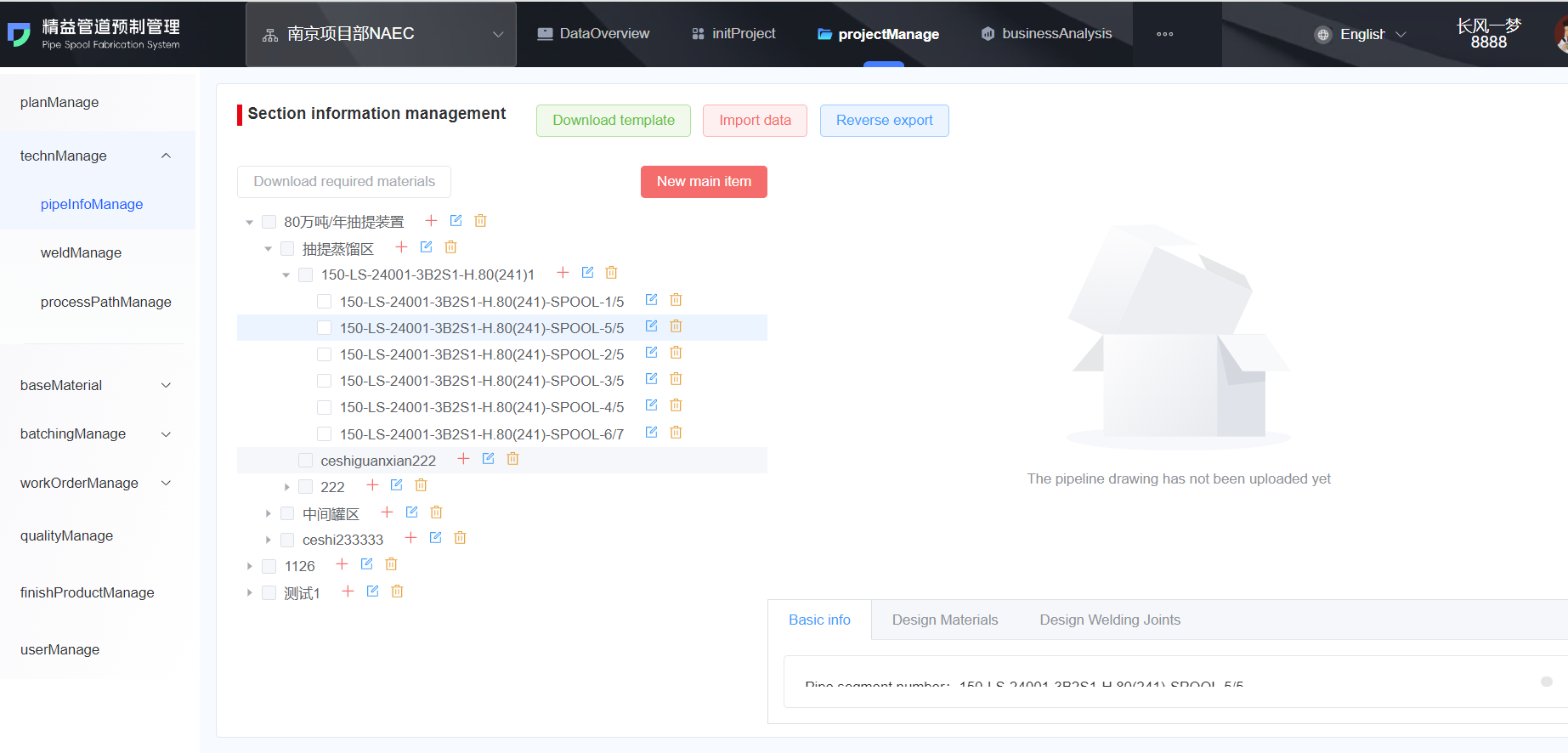

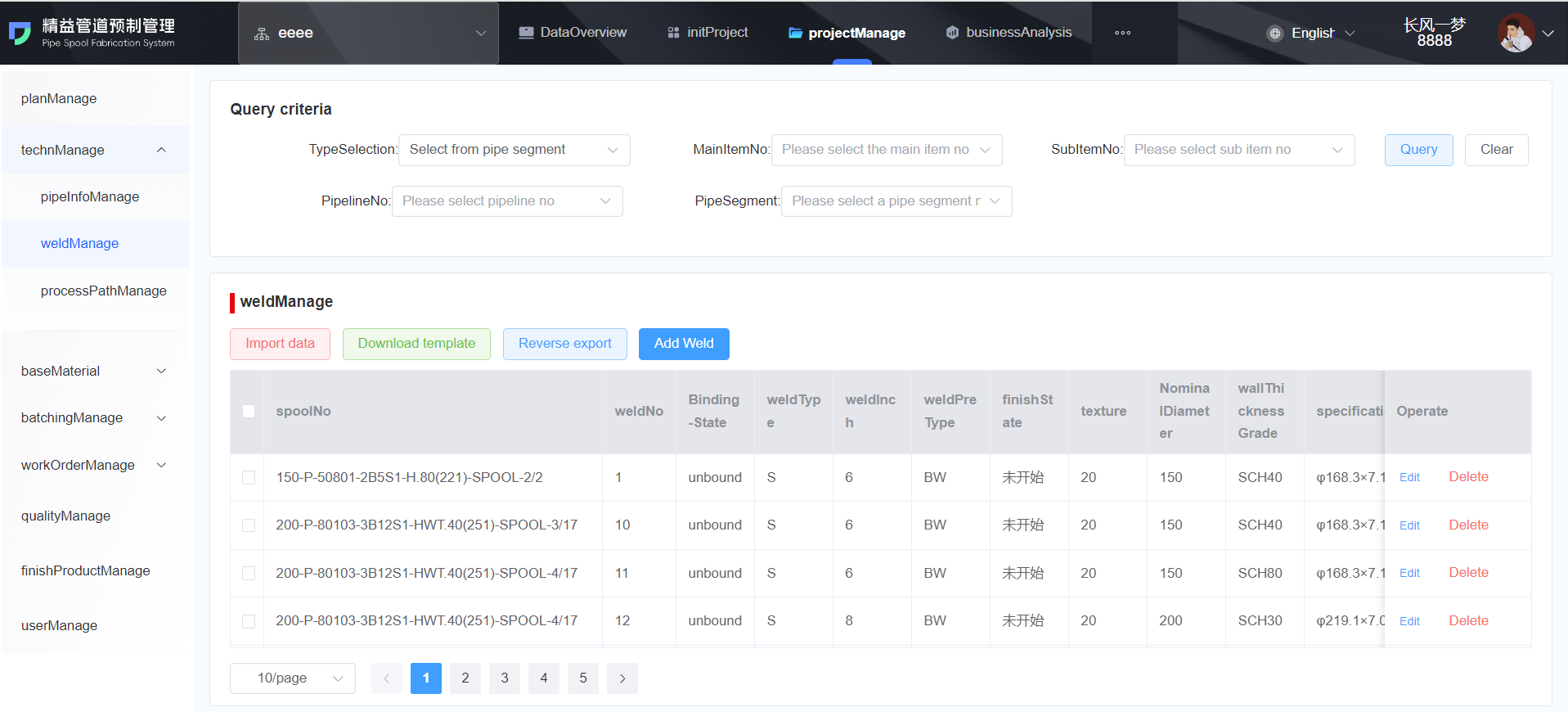

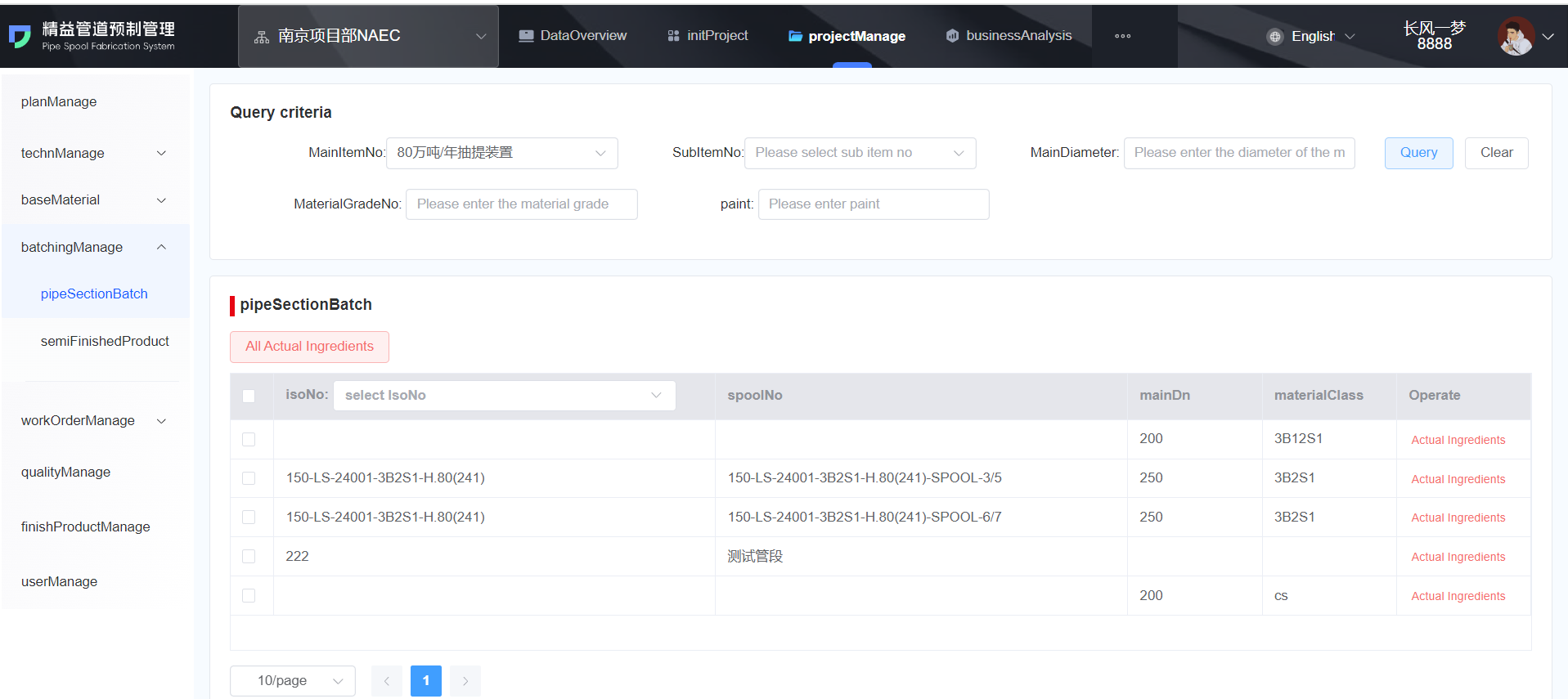

Basic Welding Information Management

NAEC Lean Pipe Spool Fabrication System manages information such as pipe materials, pipe fittings, and welding joints based on the data provided in the drawings. Utilizing NAEC's proprietary nesting algorithm, it provides optimal solutions for cutting and blanking based on drawing information and models, saving customers material costs from the source.

● Industry Pain Points

01 Relying heavily on paper drawings to guide production

02 Difficulties in distributing drawing unpacking tasks

03 Disconnection between the cutting and welding processes, resulting in a vacuum area

● Highlights of the Plan

01 Multi-format import of drawing content

02 Freely configurable drawing information

03 Reverse export of configuration content supported

04 Optimization of cutting nesting algorithm

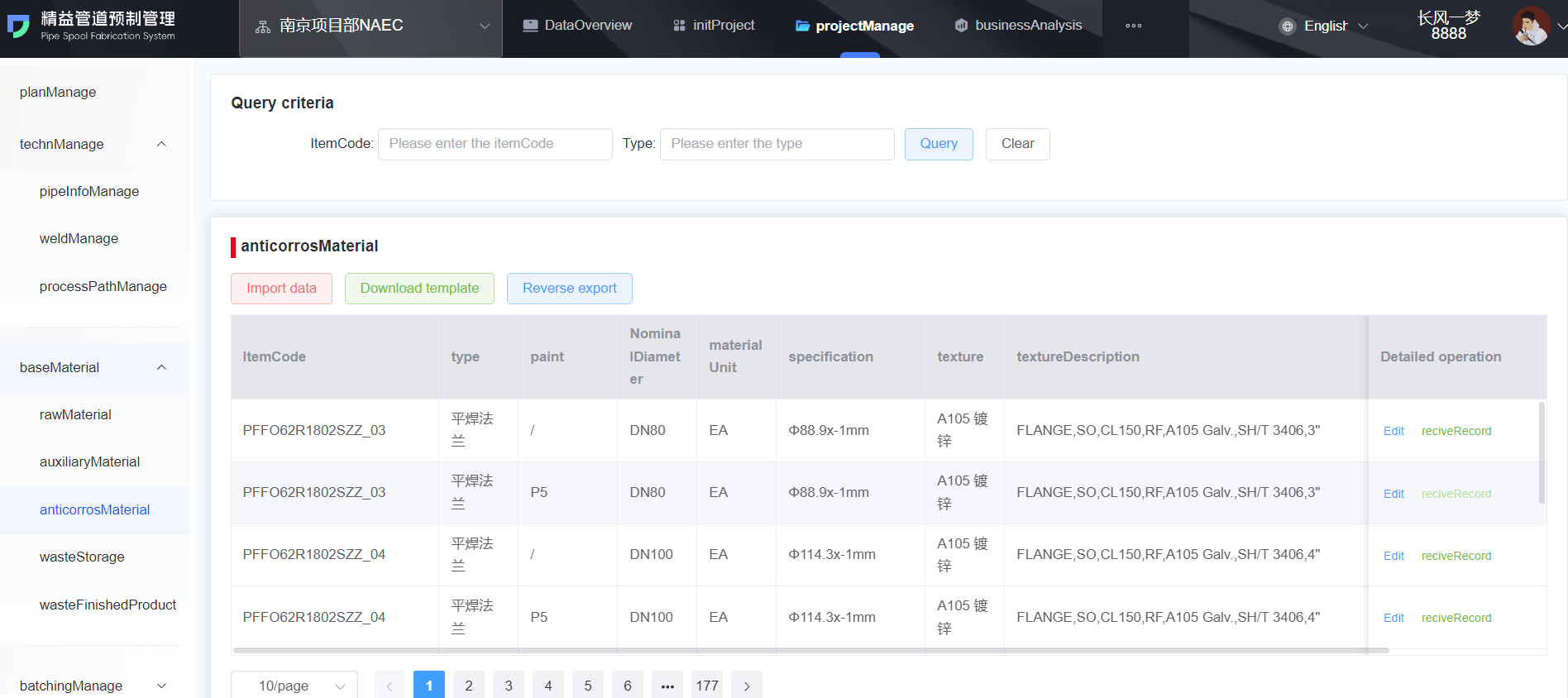

Material Management

NAEC Lean Pipe Spool Fabrication System, based on industry production models, focuses on customers' pain points, controls underlying requirements, creates new methods for production material management, and is dedicated to streamlining the internal supply chain system of production, promoting the implementation of lean production concepts.

● Industry Pain Points

01 Poor alignment between inventory materials and production tasks

02 Complex blending process requires disassembly and multiple mixing steps

03 Long time for material preparation prior to production

04 Ineffective integration between production tasks and inventory management

● Highlights of the Plan

01 Automatic matching and inspection of material inventory

02 Disassembly of blending operations and allocation of blending progress

03 Pre-production material preparation to shorten production setup time

04 Internal circulation to streamline the entire production and inventory chain

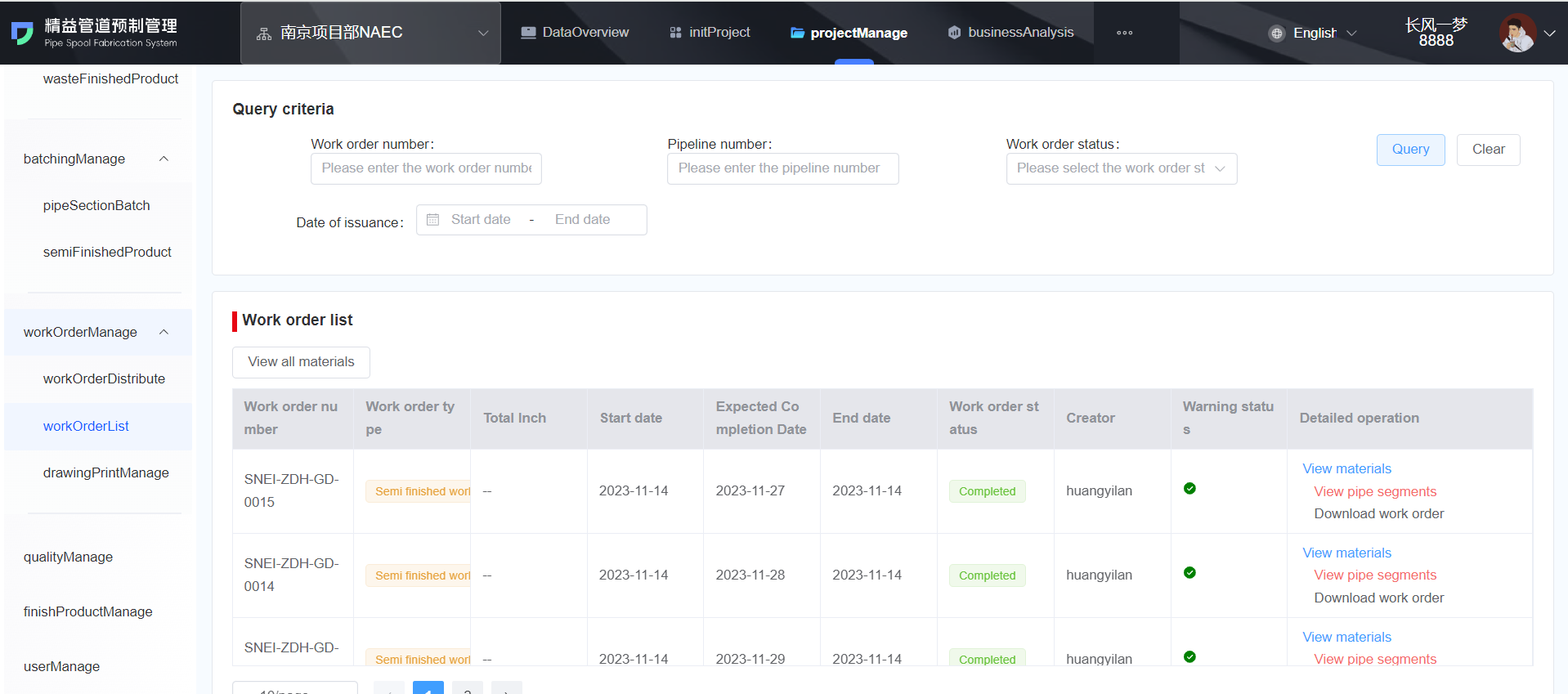

Work Order Management

NAEC Lean Pipe Spool Fabrication System, built upon years of experience in the manufacturing industry, delves deeply into production lines to understand the pain points and difficulties. It aims to alleviate on-site workloads and prioritize lean optimizations in all processes. Based on customers' production workflow systems, it creates a truly tailored work order system for production.

● Industry Pain Points

01 Lack of transparency in the production process

02 Flaws in systematic management and control measures

03 Efficiency reliant on manual efforts

04 Long feedback time with poor timeliness

● Highlights of the Plan

01 Transparent production process

02 Mobile platform supporting systematic management and control of the entire process

03 Digital work order generation to reduce manual input

04 Real-time update of production progress and timely feedback on production issues

Quality Management

NAEC Lean Pipe Spool Fabrication System, from the perspective of actual business needs, extracts key factors based on various inspection systems such as IQC, PQC, OQC, and FQC to create a unique quality management system tailored to the customer's business requirements. It emphasizes quality as the ultimate language, ensuring that products meet the highest standards.

● Industry Pain Points

01 Difficult to manage and control product quality and safety

02 Lack of timely quality feedback mechanisms

03 Inability to trace quality issues

04 Persistently high product repair rates

● Highlights of the Plan

01 Comprehensive quality monitoring mechanism

02 Quality control and timely feedback throughout the entire process

03 Monitoring of repair paths and archiving of causes

04 Quality tracing with records of quality monitoring throughout the entire process

Finished/Semi-Finished Management

NAEC Lean Pipe Spool Fabrication System, based on four key dimensions of space management, physical management, on-site management, and traceability management, is tailored to address the practical business needs and industry pain points within the pipe prefabrication industry. It specifically focuses on the management of finished and semi-finished products, aiming to address the challenges and inefficiencies commonly encountered in this field.

● Industry Pain Points

01 Large quantity of finished materials at the project site

02 Cumbersome data collection and information gathering

03 Difficulties in manual management

04 High quantity, easy to overlook or miss items

● Highlights of the Plan

01 Finished products are organized and retrieved based on project and location

02 Integration with positioning systems is supported

03 Reduction of manual involvement

04 Simultaneous issuance of finished product information and archive upon outbound delivery

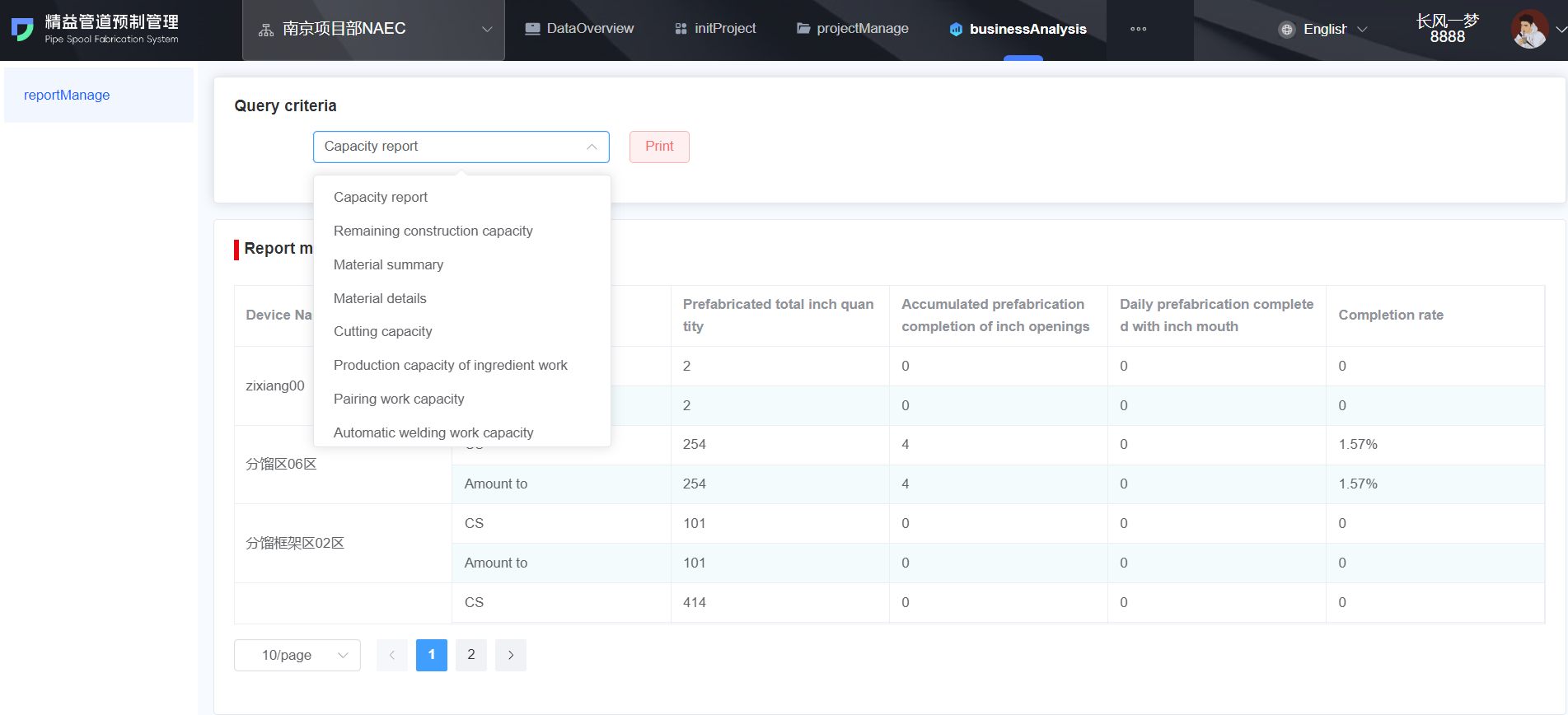

03 Business Analysis

NAEC Lean Pipe Spool Fabrication System incorporates a delivery report system recognized by the pipe prefabrication industry/enterprises (adhering to the Sinopec 3543 standard). It allows for custom report formats based on the reporting platform's functionality, currently covering design, manufacturing, delivery, and other key aspects. Through this platform, it can quickly generate reports on the entire product lifecycle, providing a production dashboard feature that displays real-time processing information.

● Industry Pain Points

01 Low level of paperless operations, difficulties in storing paper documents, and inconvenient retrieval

02 Difficulties in data collection, tracing historical data, and statistical analysis

03 Challenges in improving operations, tracking processes, verifying effectiveness, and accumulating effective improvement experiences

● Highlights of the Plan

01 Lifecycle Management Analysis

02 Quantification of Constructability Data

03Closed-Loop Management Analysis for Issues throughout the Entire Process

04 Issuance of Industry Inspection Reports for Products

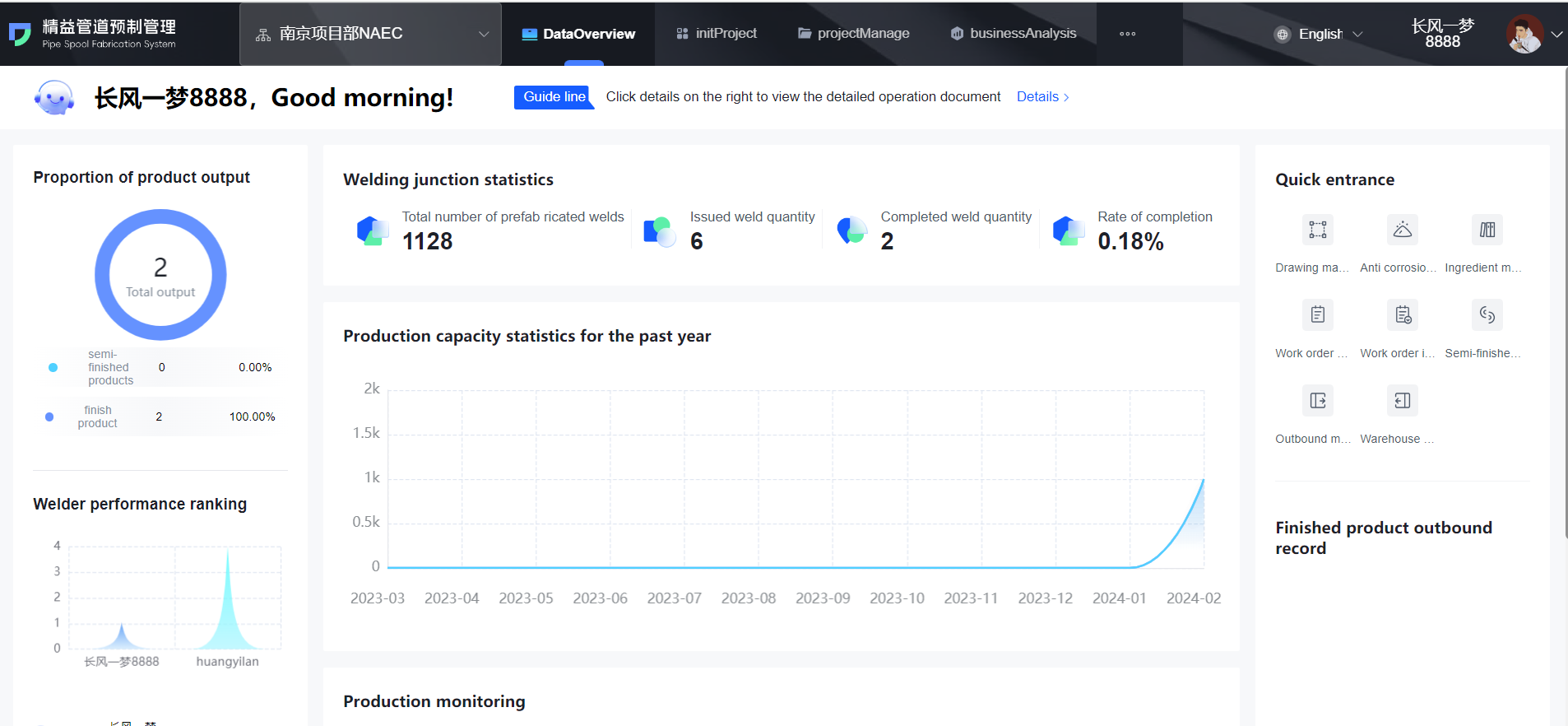

04 Data Overview

NAEC Lean Pipe Spool Fabrication System enables intelligent manufacturing enterprises to optimize their management processes, achieve transparency in the production process, and give enterprise managers a thorough understanding of production status. It simplifies information density, provides desktop-style management, and adds quick access to key process modules, assisting users in becoming proficient and operating with ease.

● Highlights of the Plan

01 Data visualization

02 Functional windowing

03 Simplification

04 Status perception and early warning

05 Overall production visualization

Scan the QR code to read on your phone

Relevant news

Address: No. 1 Zhongxing West Road, Lishui District, Nanjing, Jiangsu, China

Email:auto@autowelds.com

WeChat public number