News

NAEC Intelligent Welding Management System

- Categories:News

- Author:

- Origin:

- Time of issue:2022-07-15 18:29

- Views:

(Summary description)

NAEC Intelligent Welding Management System

(Summary description)

- Categories:News

- Author:

- Origin:

- Time of issue:2022-07-15 18:29

- Views:

Based on the persistent researches on intelligent technologies, combined with many years’ experiences on welding, NAEC successfully releases the intelligent welding management system. From lean fabrication to intelligent lean fabrication, NAEC always deeply understands customers’ demands; from automatic welding to intelligent welding, NAEC still sticks to the original intention, realizes continuous breakthrough in the welding field.

The intelligent welding management system includes seven sections, which are:

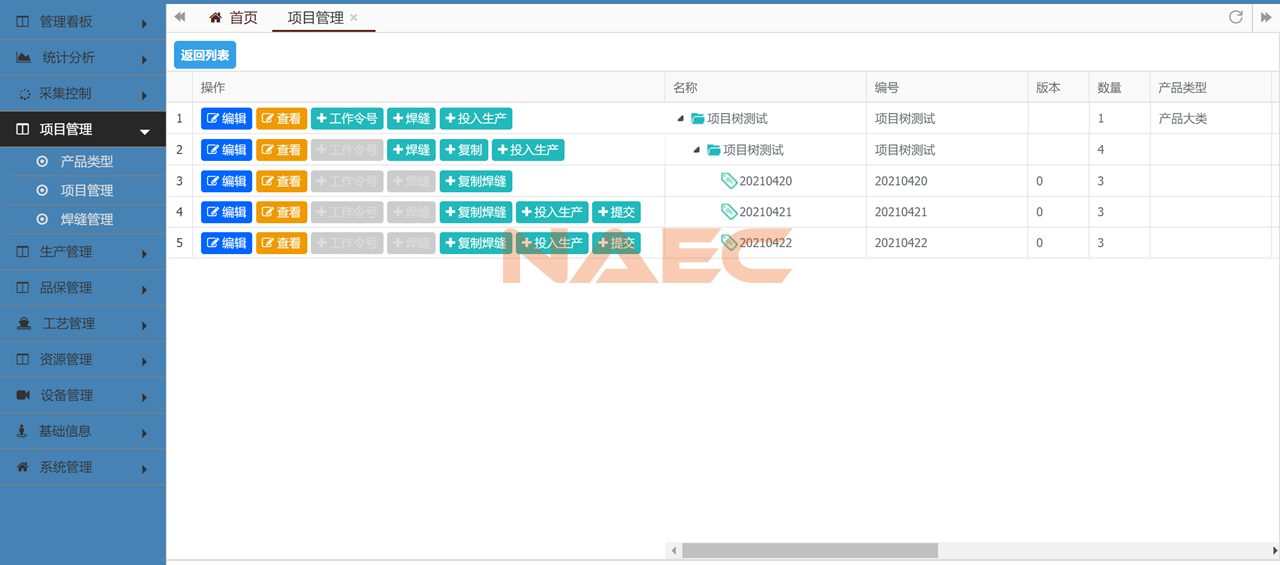

- Project management

●Manage and display at the level of Project-> Work Order-> Component (optional) -> Welding seam-> Layer, so as to put into production by project, work order or welding seam.

●Realize the editing and approval function of the welding seam, welding seam copy and reuse is available, decompose the welding seam into the layer to realize the precise welding management, and each welding seam/ each layer can be set with different welding parameters and inspection requirements

●Support the whole process replication of the work order number and the process replication of the welding seam level

●Support the revision management of process cards.

- Workpiece management

The system provides the workpieces information maintenance, including the workpiece number and description. If it needs to be connected with the MES system, the workpiece information should be consistent with MES system.

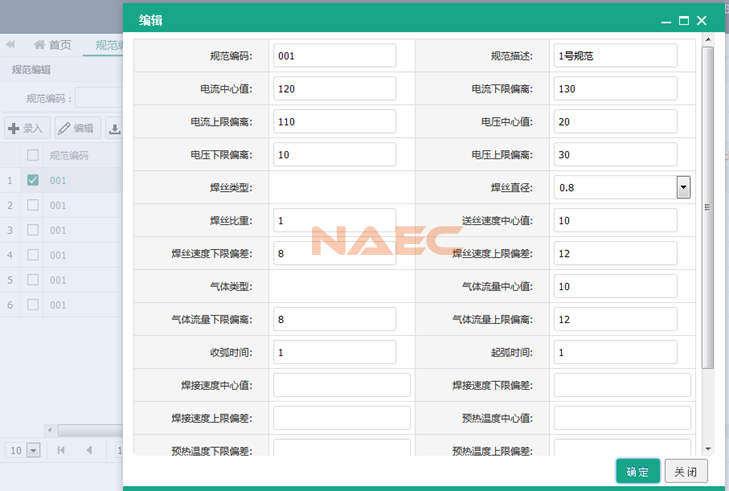

- Process management

The edited parameters of welding procedure can be verified with the real-time data of the welding machine, which can be used as the basis to judge whether it is out of standard or not, also the welding procedure data can be sent to the welding machine channel.

Able to finish electronic management of welder qualification, establishment of digital welder files, pre warning before certificate expiration, and certificate information can be reviewed by other modules, and welder qualification is associated with process procedures and process evaluation etc.

- Work list management

Connected with the MES system, find out all the open work list task information, select the welding work list by the production dispatcher, generate the welding work list of the welding system after confirmation, and then generate, maintain, schedule and dispatch the work list by the production dispatcher.

- Worksite management

The welders select the work list tasks and perform the welding according to the required workpiece welding process. The system distributes the required process parameters to equipment and locks the equipment parameters, In the process of welding, it gives a real-time alarm if the process exceeding the specification, and records the current and voltage values during the alarm.

Welders can establish an association with the welding machine by swiping the card, and check their work list and detailed welding tasks through the touch control all-in-one machine or MES terminal, and perform the welding according to the process requirements.

- Inspection management

The system inspects the workpiece through work list, which can check each welding seam or process of the workpiece, and upload the inspection report.

- Visualization management

Data visualization is divided into welding data visualization, business data visualization and business status visualization. The objectives of visualization are:

●Realize the management, statistics, analysis and display of various data;

●Real-time online monitoring of the dynamic information and status information of each module business;

Through the intelligent welding management system, it makes the whole welding process more controllable, which assists customers to obtain high welding quality, meanwhile, reduce the production cost, further to help customer establish an efficient intelligent workshop.

Scan the QR code to read on your phone

Relevant news

Address: No. 1 Zhongxing West Road, Lishui District, Nanjing, Jiangsu, China

Email:auto@autowelds.com

WeChat public number